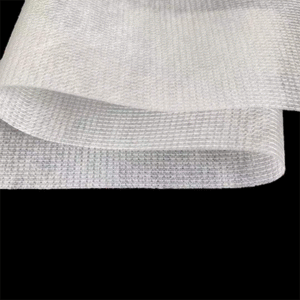

RPET nonwoven fabric (Recycled Polyester Nonwoven) is an eco-friendly textile material made from recycled polyethylene terephthalate (RPET), primarily sourced from post-consumer plastic bottles (e.g., water bottles, beverage containers). Through processes like cleaning, shredding, melting, and spinning, discarded PET products are transformed into high-performance nonwoven fabric. It combines sustainability with functionality and is widely used in apparel, bags, home textiles, and packaging.

1. Key Features of RPET Nonwoven Fabric

✅ Eco-Friendly Material: Made from recycled PET, reducing petroleum consumption and plastic waste.

✅ Performance Comparable to Virgin PET: High strength, abrasion resistance, and wrinkle resistance, with some properties surpassing conventional nonwovens.

✅ Recyclable: Supports circular economy principles and sustainable development.

✅ Customizable: Can be treated for water resistance, flame retardancy, printing, etc.

❌ Slightly Higher Cost: Due to complex recycling and processing, prices are typically 10%-30% higher than standard PET nonwovens.

2. Manufacturing Process

- Collection & Sorting: Discarded PET bottles are collected, with labels and caps removed.

- Cleaning & Shredding: Bottles are cleaned and crushed into PET flakes.

- Melting & Pelletizing: Flakes are melted and extruded into RPET pellets.

- Spinning & Fabric Formation:

- Nonwoven Process: Spunbond, meltblown, or needle-punching techniques are used.

- Special Finishing: Some products undergo lamination, calendering, or compositing for enhanced performance.

3. Primary Applications

(1) Apparel & Bags

- Sustainable Clothing: Sportswear, outdoor jackets (e.g., brands like Patagonia use RPET fabric).

- Backpacks/Tote Bags: Lightweight and durable, popular among eco-conscious brands.

(2) Home Textiles

- Upholstery Fabric: Stain-resistant and breathable, ideal for modern furniture.

- Curtains/Tablecloths: Can be treated for water resistance or UV protection.

(3) Packaging Materials

- Luxury Packaging: Lining for gift boxes, eco-friendly shopping bags.

- Electronic Protective Sleeves: Cushioning material to replace traditional foam.

(4) Industrial Uses

- Filtration Media: For air or liquid filtration systems.

- Automotive Interiors: Seat liners, door panel covers.

4. Environmental Benefits & Certifications

- Resource Conservation: 1 ton of RPET saves ~6 tons of petroleum.

- Reduced Emissions: 50% lower energy consumption vs. virgin PET production.

- Certifications:

- GRS (Global Recycled Standard): Requires ≥20% recycled content.

- OEKO-TEX®: Ensures no harmful chemical residues.