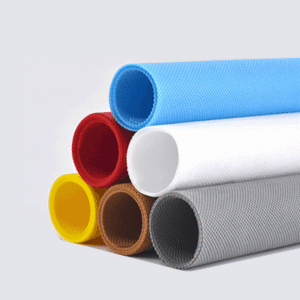

PP nonwoven fabric (polypropylene nonwoven fabric) is a type of nonwoven material made primarily from polypropylene (PP) through nonwoven manufacturing processes such as spunbond, meltblown, thermal bonding, or needle punching. Below are its key characteristics and applications:

1. Key Features

- Lightweight & Soft: Comfortable for direct skin contact.

- Hydrophobic: Naturally water-resistant but can be treated for hydrophilicity.

- Chemical Resistance: Resistant to acids, alkalis, and organic solvents.

- Antibacterial: PP inherently resists bacterial growth, making it ideal for medical and hygiene products.

- Customizable: Can be modified with additives (e.g., color masterbatches, flame retardants).

- Eco-Friendly: Recyclable, and some variants are biodegradable (e.g., with photodegradable additives).

2. Manufacturing Processes

- Spunbond: Melt-spun PP fibers are laid into a web and bonded, producing strong fabrics (e.g., for shopping bags).

- Meltblown: Ultra-fine fibers create dense, high-filtration layers (e.g., for surgical masks).

- Thermal Bonding: Heat-pressed for softness (e.g., wipes, sanitary products).

- SMS Composite: Combines spunbond (S) and meltblown (M) layers for strength and filtration (e.g., medical gowns).

3. Applications

- Medical & Protective Gear: Surgical masks, gowns, sterilization wraps (meltblown PP is key for N95 filters).

- Hygiene Products: Diaper liners, sanitary napkins, wet wipes (soft and breathable).

- Packaging: Reusable shopping bags, gift wraps (printable, eco-friendly alternative to plastic).

- Industrial/Home Use: Furniture lining, air/water filters, agricultural mulch (weather-resistant).

- Others: Car interiors, geotextiles (e.g., road reinforcement).

4. Environmental Impact

- Recyclable: PP can be melted and reprocessed but requires proper sorting.

- Biodegradability: Conventional PP degrades slowly; bio-based or additive-enhanced versions improve sustainability.

- Eco-Advantage: Lower energy consumption in production vs. traditional plastics.